General Purpose

Our general purpose grade is fit for a huge range of applications. Available in all formats and any colour. Produced in 4 standard densities (P10, P16, P24, P33), with custom densities also available to suit the intended application.

View DatasheetFurther Information

PremSil General Purpose silicone sponge is our range of cellular silicone with a closed cell structure and smooth outer surface, particularly suited to demanding temperature applications requiring a soft compressible material. Our material offers excellent thermal resistance from -50°C up to +250°C, excellent resistance to UV, Ozone and weathering and an excellent compression set <15% typical.

PremSil GP grades are available as extrusions, tubes & hoses, cord and sheets. Sheets and cord can be converted in-house to gaskets and o-rings. Most sizes can be manufactured to the tightest tolerances upon request with E3 tolerances promised as standard. General Purpose materials are manufactured in 4 densities (see datasheet). We can also formulate custom densities to meet requirements if the project requires a specific density. Available in custom colours to fit the applications surroundings.

Applications

Sealing, gaskets, O-rings, extreme temperatures, vibration dampening, thermal insulation, industrial rollers, paper making, flexibility, weather resistance, noise reduction + more.

HIGH TEMPERATURE

Manufactured specifially for demanding applications where the product must withstand extreme temperatures, our HT grade is available in P10 – P33 and able to withstand temperatures of -50C to +280C.

View DatasheetFurther Information

PremSil Silicone sponge offers fantastic thermal resistance as standard. Our PremSil High Temperature sponge is a specially formulated material designed to offer the same properties as our PremSil General Purpose, whilst also offering an improved temperature resistance up to +280°C continuously. It maintains its closed cell structure, smooth outer skin, resistance to UV, Ozone & weathering and excellent compression set. PremSil HT is particularly suited to extreme high temperature applications demanding a compressible material with great recovery.

PremSil HT Silicone Sponge is available as extrusions, tubes & hoses, cord and sheets. Sheets and cord can be converted in-house to gaskets and o-rings. PremSil HT is manufactured in 4 densities (see datasheet). Most sizes can be produced up to the tightest tolerances upon request with E3 tolerances promised as standard. Custom colours available.

Applications

Sealing, gaskets, O-rings, extreme temperatures, thermal insulation, industrial rollers, paper making, flexibility, weather resistance + more.

FLAME RETARDENT

Our PremSil FR silicone sponge is perfect for applications requiring a material able to overcome the risk of fire. Independantly tested and certified to UL94-V0 standards, PremSil FR proves a reliable solution. Available in P16- P33.

View DatasheetFurther Information

Naturally, silicone is a flame-retardant material and will self-extinguish. Most grades we offer will meet UL94-HB minimum, however there are many applications which require higher standards to be met when considering fire safe materials. PremSil FireSafe has been specifically formulated to overcome the risk of fire and has been independently tested and certified to UL94-V0 standards. We manufacture PremSil FireSafe in 3 densities, from P16 – P33, and offer custom colours to suit.

PremSil FireSafe is available as extrusions, tubes & hoses, cord and sheets. Sheets and cord can be converted in-house to gaskets and o-rings. Most sizes can be produced up to the tightest tolerances upon request with E3 tolerances promised as standard.

PremSil also offers a low smoke/low toxicity flame retardant grade certified to EN45545-2 R22/R23 standards for speciality sectors and applications such as rail and mass transit. Click here to find out more.

Applications

Sealing, gaskets, O-rings, extreme temperatures, vibration dampening, thermal insulation, industrial rollers, paper making, flexibility, weather resistance, noise reduction + more.

FDA SILICONE SPONGE

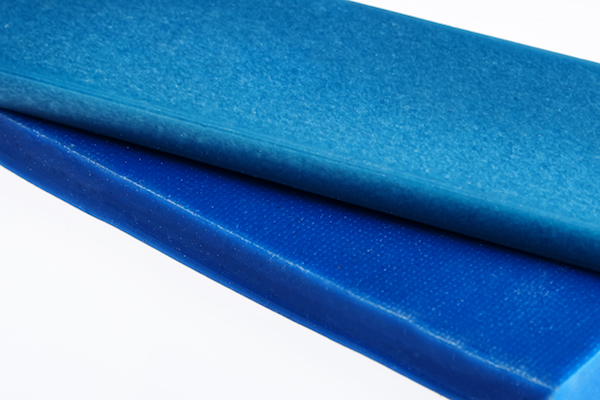

PremSil P201F FDA is our platinum cured, fully compliant FDA silicone sponge, perfect for food & beverage and many medical applications. Manufactured with only pre-approved materials according to FDA 21 CFR 177.2600 and tested to the same FDA regulations. Available in White & Blue colour. 400Kg/m3

View DatasheetFurther Information

Whilst there are several FDA approved elastomers on the market, silicone is certainly classed as the ‘go to’ for FDA requirements, thanks to a variety of excellent properties. PremSil P201F is our platinum cured FDA approved Silicone Sponge that has excellent temperature resistance, withstanding extreme temperatures from -50°C up to 220°C. P201F also has good chemical resistance to many chemicals and oils that are commonly present in areas where consumables may be handled or processed. Couple these properties with our sponge’s excellent elasticity, compression and flexibility and you have a highly reliable silicone sponge rubber, great for repeated use in equipment, food processing and machinery.

Manufactured in a medium density to suit a wide range of applications, PremSil P201F FDA is available in white and blue as standard and as extrusions, tubes & hoses, and cord. Most sizes can be produced up to the tightest tolerances upon request with E3 tolerances promised as standard.

Applications

PremSil P201F FDA is perfectly suited to many applications within but not limited to the food & beverage and pharmaceutical industries, including sealing, gaskets and high temperature applications demanding a soft compressible material with an excellent compression set.

PREMSIL P20 FOODSAFE

A custom made grade with medium density of approx. 300Kg/m3. Tested and compliant to FDA 21 CFR 177.2600 extraction tests (Sect. E-F), PremSil P20 FS proves a cost effective and popular solution for multipurpose applications.

View DatasheetFurther Information

PremSil P20 FoodSafe is our specially formulated closed cell silicone sponge with a smooth outer skin, compliant to FDA 21 CFR 177.2600 extraction tests sections e & f. It has a medium density for multipurpose applications, excellent temperature resistance -50°C to +200°C and a good compression set <15%, making it great for sealing applications. P20 FoodSafe proves a cost-effective solution for many food & beverage applications.

Manufactured as extrusions, tubes & hoses, and cord, P20 FS is also available in custom colours to suit your application requirements. Most sizes can be produced up to the tightest tolerances upon request with E3 tolerances promised as standard. End users should ensure it is a suitable solution for the intended use. If a fully FDA approved product is required, PremSil P201F FDA meets all necessary requirements.

Applications

PremSil P20 FoodSafe is a cost effective solution for indirect food contact applications and perfectly suited to high and low temperature sealing applications.

RAIL GRADE

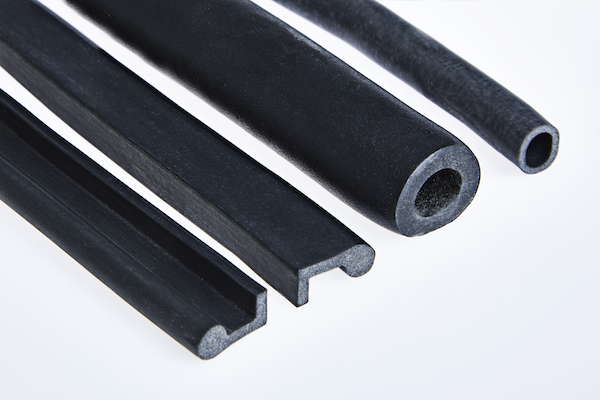

PremSil PSSRG-250 is one of our specialty grade silicone sponges, formulated specifically for the rail industry. Compliant to EN45545-2 this low smoke/low toxicity sponge is well suited a multitude of applications. Black/Grey colour.

View Datasheet View BrochureFurther Information

The rail and mass transit industry is rapidly growing globally with an increasing demand for products that provide sealing and dampening solutions. EN45545 requirements set the standard for passenger safety and protection from fire. These strict regulations demand materials meet specific criteria for both internal and external applications.

PremSil has developed a closed cell silicone sponge that meets the priority requirement of passenger safety according to EN45545-2 R22/R23. PremSil RG-250 is a lightweight, medium soft silicone sponge offering fantastic sealing properties. Its high-temperature resistance means it can excel in extreme temperatures with low smoke, low toxicity and flame resistance – compliant to UL94V0. Coupled with a very low compression set and great durability, it is a first class solution for many industry applications.

Applications

Interior/Exterior Gaskets & Seals, interior door seals, lighting gaskets, HVAC seals, smoke seals, gap fillers, enclosure seals, moisture & dust seals, panel seals, LCD Gaskets, exterior door seals, exterior lighting seals, window seals

FDA Vs. FoodSafe or FDA compliant – what’s the difference?

We are one of the very few manufacturers that can provide a full approved FDA silicone sponge. There is quite a lot of confusion surrounding compliance to FDA regulations and much of this confusion stems from the description of the product. The clear majority of FDA sponge products on the market are described as ‘compliant to FDA 21 CFR 177.2600’. This generally means that meets the extraction testing requirements. This does not mean it is fully FDA compliant or approved though.

So, what does it mean?

FDA 21 CFR section 177.2600 specifically refers to elastomers, such as silicone, and sets the general rules for rubber articles intended for repeated use in the food industry. Paragraphs A – D describe the regulations for Rubbers intended for repeated use and lists the ‘safe’ ingredients that may be used in the production of the product – this is sometimes referred to as the FDA Whitelist.

The article also outlines and emphasises the point of such rubbers being suitable for repeated use, meaning it shouldn’t harbour any contaminants just as it shouldn’t give them off. The product must, therefore, undergo extraction tests in water & n-hexane, outlined in paragraphs E & F, to show it meets the extraction limits set.

For the product to be fully compliant it must meet both these extraction limit requirements and only contain ingredients from FDA’s whitelist – this is where most products fall short. Many sponge products are compliant to the extraction limits but contain ingredients that have not been permitted by FDA, such as peroxides, making them suitable for contact with foodstuffs (FoodSafe) but not FDA Approved.

How do you know you’re getting the right product?

It can be very hard to distinguish which it is you’re getting when placing orders with manufacturers. Which is why we take it upon ourselves to make sure our customers aren’t misled and know exactly what they’re getting every step of the way.

PremSil Products

At PremSil, we are proud to offer fully FDA Approved silicone sponge products, using only ingredients permitted and meeting the test requirements set in FDA 21 CFR 177.2600 alongside a range of FoodSafe products. This means no matter what your requirement is, you know you’re safe with us.